Zero Manual Handling – When It Matters Most. A leading pet food manufacturer recently ordered[…]

Precision and Safety with Mechandling’s Bespoke Design A major pet food manufacturer recently ordered several[…]

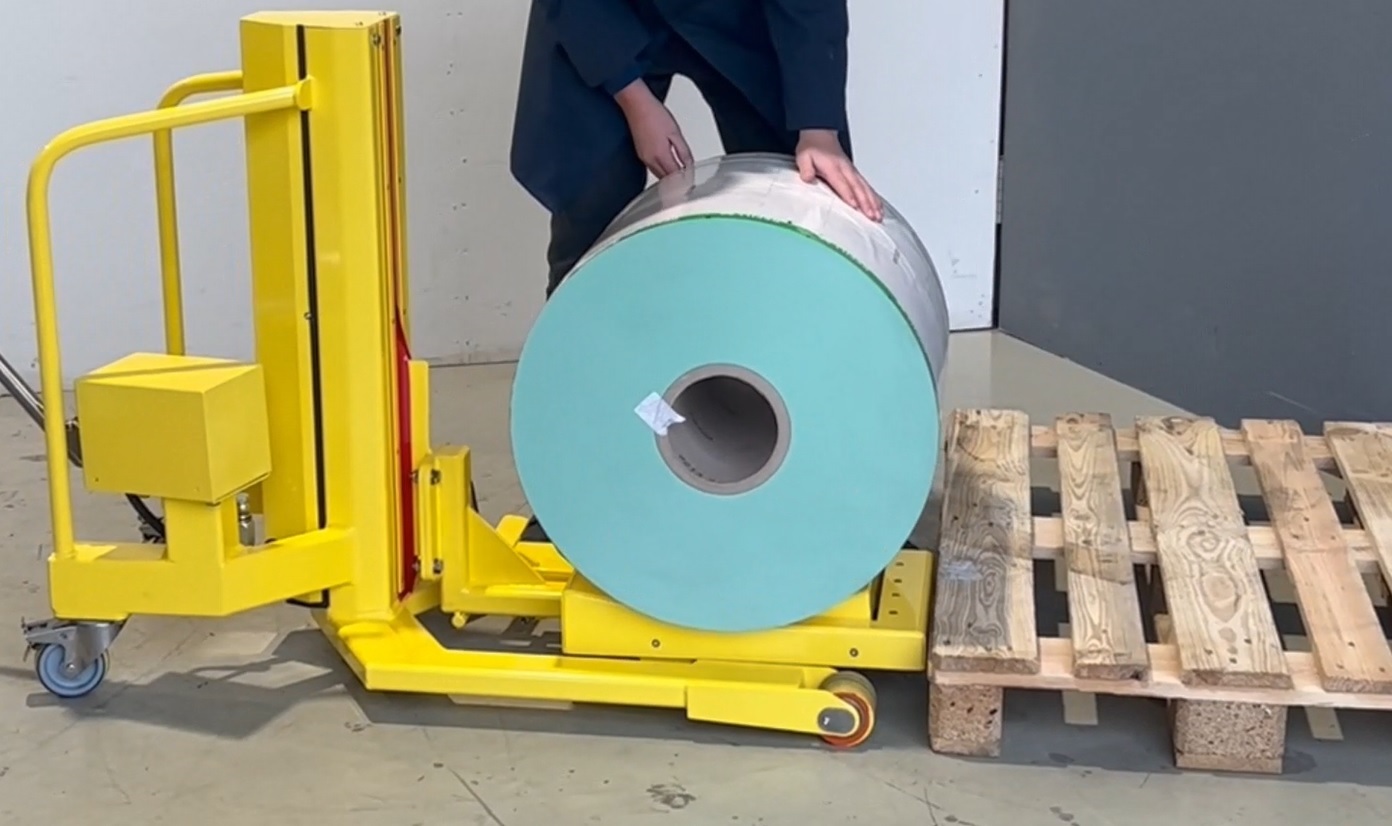

Mechandling Eliminate Risks To Operators Loading Heavy Reels. We were recently asked by an international[…]

The Mechandling Reel Loader Revolutionises Reel Handling! One of the UK’s premier pet food manufacturers[…]

Struggling With Lifting Issues? Mechandling Can Help! Once again, Mechandling show the benefits of Bespoke[…]

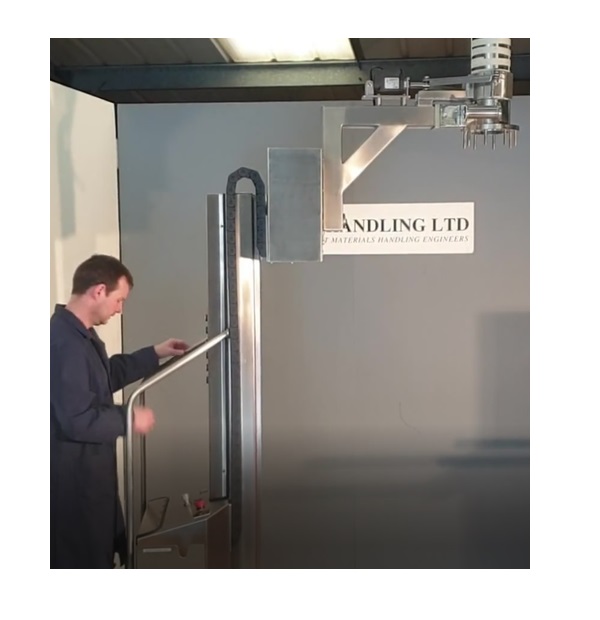

Platform Lifter Removes H&S Risks. Our latest manual platform lifter has become a welcome addition[…]

An Old Favourite With A Twist! Mechandling introduce a new design to our portfolio of[…]

Mini Lifter Saves The Day! We were recently asked by a large UK pharmaceutical manufacturer[…]

Mechandling remove heavy lifting injury risk completely! Are your operators lifting dangerously heavy weights? We[…]

400kg Tablet Tipping Made Easy! A top pharmaceutical manufacturer recently enquired about a bin tipper[…]

Mechandling Unveil Our Latest Isolator Drum Tipper (docking at height) A major Irish pharmaceutical manufacturer[…]

Mechandling Successfully Collaborate With Howorth Air Tech Again! Once again, Mechandling have collaborated with Howorth[…]

A Lifter Within A Lifter – A Totally Bespoke Solution! Mechandling once again prove that[…]

Double Reel Lifter Increases Productivity & Safety Mechandling are proud to reveal our latest powered[…]

Mechandling Do It Again! We were recently tasked with finding a reel handling solution for[…]

Mechandling Proud To Deliver Our Latest Game-Changing Lifters! As everything we make is 100% bespoke,[…]

Mechandling To The Rescue! We were recently asked to design a manual lifter for a[…]

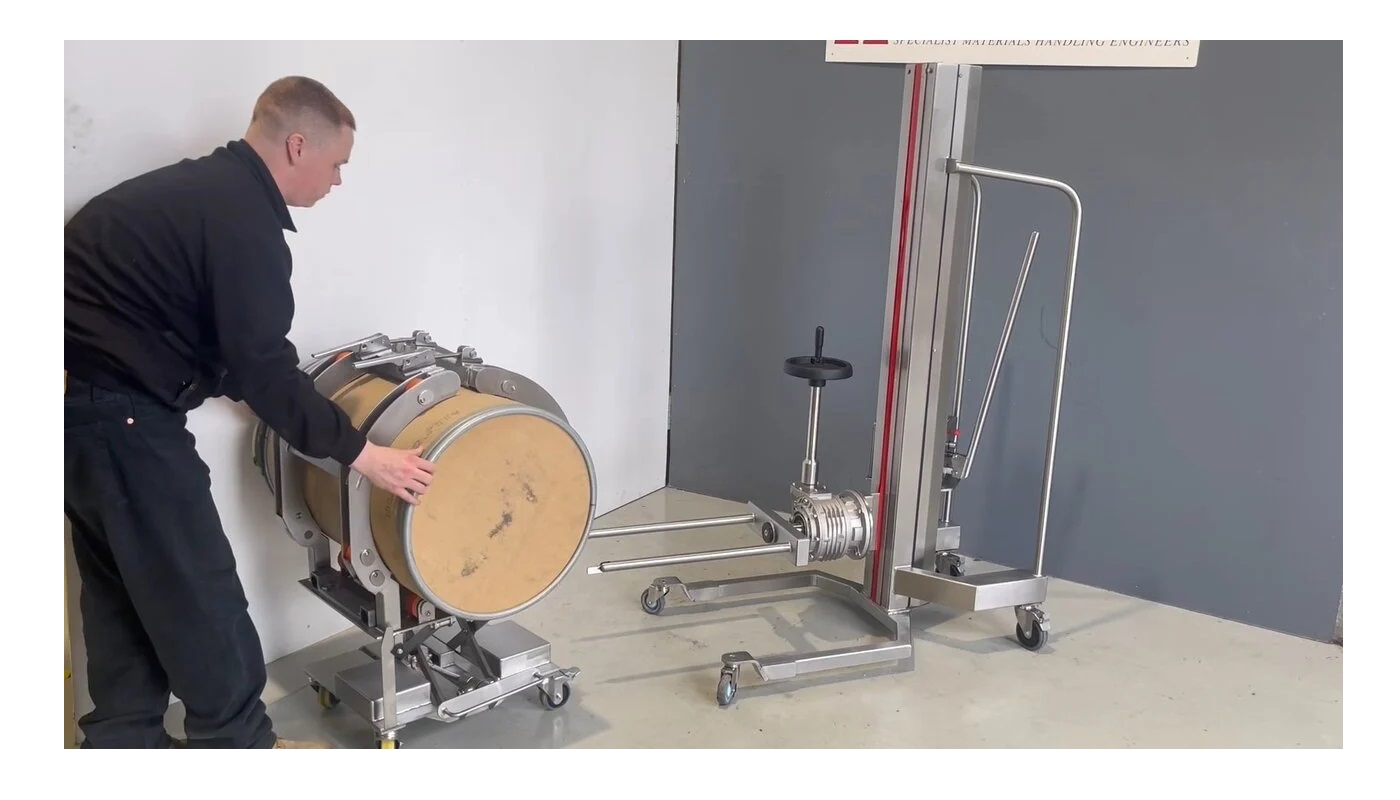

Mechandling Proudly Unveil Our Latest Bespoke Stainless-Steel Drum Tipper Mechandling are proud to announce the[…]

Mechandling Celebrate Completion Of Our 1000th Lifter Mechandling are delighted to announce the recent completion[…]

Mechandling Commit To Reducing Our Carbon Footprint To paraphrase (Edmund) Burke: The worst thing you[…]

Mechandling Expansion Gets Underway Despite the unusual last eighteen months we have all had,[…]

Great Feedback On Our Steel Rod Manipulator At Mechandling, we pride ourselves on being versatile[…]

Telemast Drum Tipper – ATEX Creating one-off bespoke designs to help customers overcome dangerous and[…]

Static Twin-Column IBC Lifter At Mechandling, we love what we do. Designing bespoke lifters for[…]

Tablet Bin Tipper At Mechandling, we make all our lifters by hand. Designing a completely[…]

Oh Boy – alignment and accuracy the order of the day At Mechandling, we make our[…]

Manual ATEX Drum Lifter – A Compact Heavyweight At Mechandling, we make our material handling[…]

Bespoke Design In Action This month we had the pleasure of making 2 of our[…]

Heavy-Duty Reel Rotator At Mechandling, all our lifters are hand made to order, tailored to[…]

Mechandling Long-Reach Reel Placer In November we exported one of our Long Reach Reel Placers[…]

Mechandling Power Lift Table In October we had an urgent call from a good customer[…]

Mechandling Self-Propelled Telemono IBC Vessel Inverter Mechandling’s brand new development for 2018, the Stainless Steel[…]

Mechandling ATEX Ultra Mechandling are proud to announce that we now provide ATEX versions of[…]

Mechandling New Self-Propelled Lifter Mechandling introduce a new self propelled Lifter to join the powered[…]

Mechandling win award from BAE systems M.D. Stephen Young was presented with a bronze award[…]

Reel Slide Loader The Reel Slide Loader mechanism is a new design for lifting and[…]

Twin Ultra Lifter A brand new update to our popular Ultra Lifter chassis, the “Twin[…]

Offshore Oil Platform Oil Heater Trolley Mechandling can include the Offshore Oil industry amongst their[…]

01260 299411

01260 299411